One sensor, countless possibilities!

Customers who already rely on our technology

João Pedro Azevedo

Innovation Business Partner - ArcelorMittal

The team (at Hedro) was always, always, always available to be one step ahead of what we were looking for as solutions. The team always sought to go further, develop new things, test new features. We were very happy to work with Hedro.

Daniel Moraes

Digital transformation and innovation manager - TUPY

Hedro, together with the innovation, maintenance and digital transformation teams, applied its sensors to critical equipment during the proof of concept. As a result, we verified the failure prevention capacity that the Hedro solution has, as well as its robustness and reliability. Another highlight was the quality and level of service from the Hedro team, which worked very collaboratively with the teams

Why choose Hedro?

Hedro connects old machines to the internet of things.

Have production data without having to invest in more modern and expensive machines.

We enable innovation initiatives that require machine and process data

Easy to install, configure and use sensors

Rugged hardware for harsh environments

Sensors that can “walk around the factory” along with the equipment

Super secure data system, prepared to operate in the cloud or on-premises

Streaming data to customer and partner APIs in real time

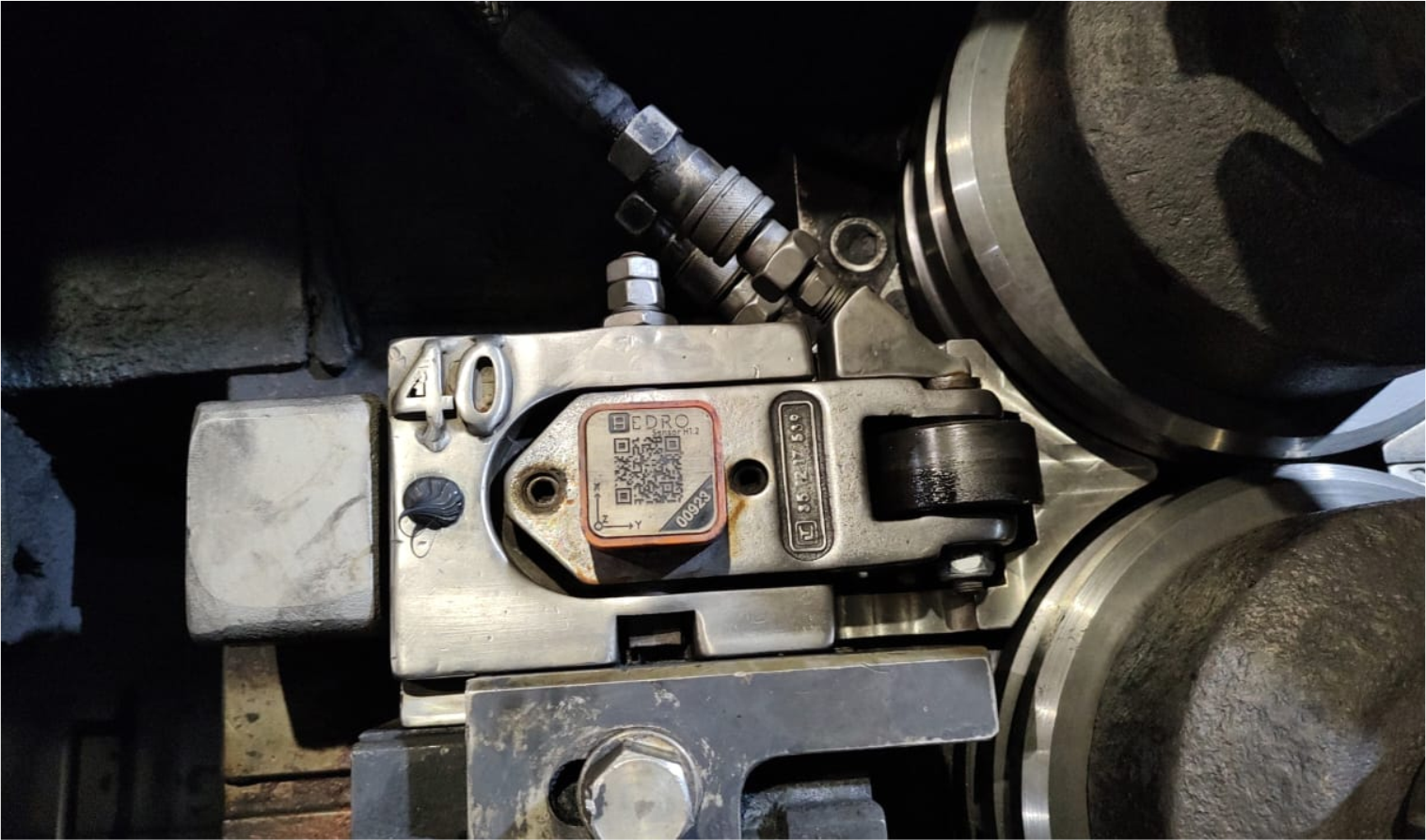

Digitalization of Steel Rolling Mills

In the Steel Industry, H1.3 sensors are enabling the digitalization of machines and processes with incredible results.

Digitize and monitor rolling mill stability in real time

Predict catastrophic failures in the process, with the help of the ADL Intelligence system (Dynamic Lamination Analysis) developed by Hedro.

With H1.2 + ADL Sensors our customers can

Improve production indicators

Identify flaws that lead to quality problems in finished products

Improve efficiency and pace of operation

Predict the occurrence of scrap in the rolling process

Reduce operators’ exposure to operational risks

In the Steel Industry, H1.3 sensors are enabling the digitalization of machines and processes with excellent results

HOUR

in advance to predict failures in the process.

TONS

of scrap in the rolling mill avoided per year

LESS

mechanical faults on the process

HOURS

of production per year

Customers already using Hedro to digitize their operations and machines:

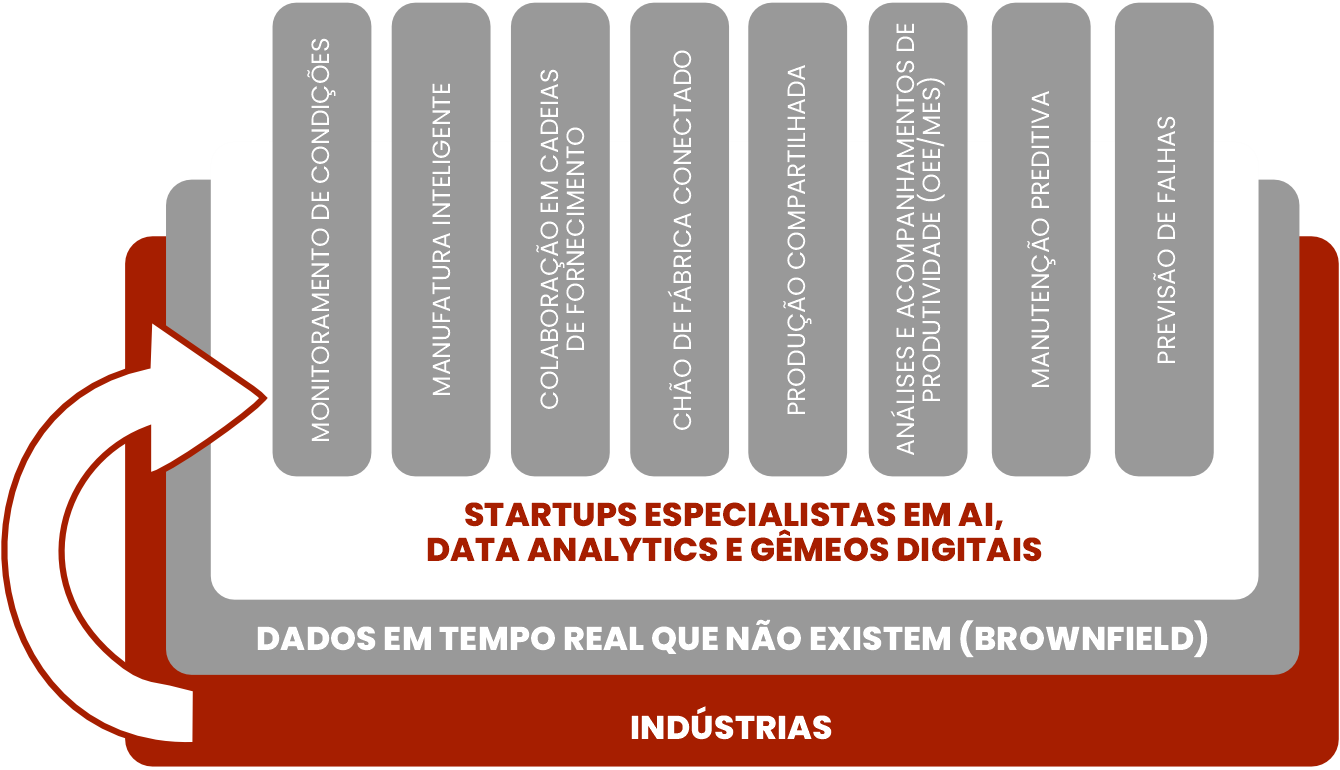

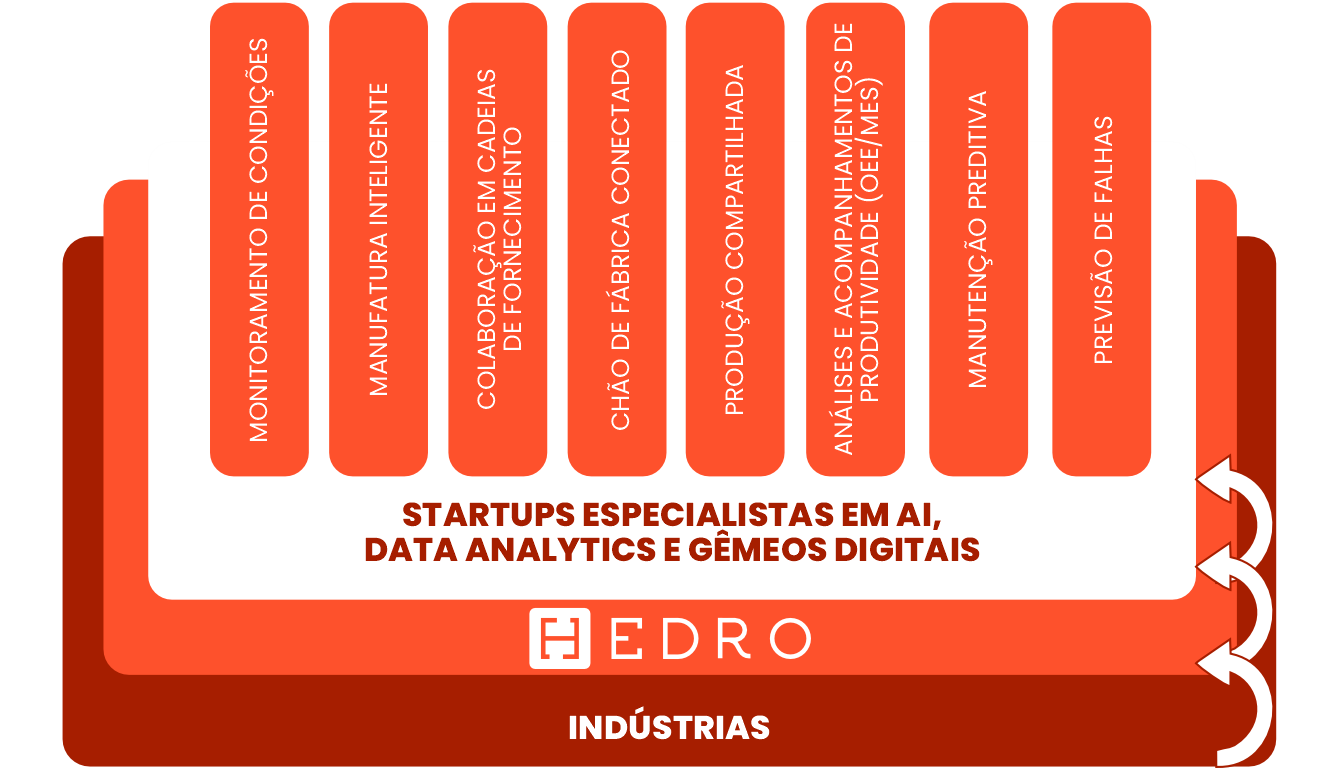

Industry 4.0 enabler

If your company generates value with industrial data that does not yet exist, Hedro is the ideal solution to enable and enhance your business.

Check out the advantages

COLLECTION AND VIABILITY

We collect and enable data from industrial machines directly in your solution's API.

TIME TO MARKET

Reduce your product's time to market.

SCALABLE

You can trust in a scalable and industry-validated hardware.

REDUCE INVESTMENT

Reduce investment in high CAPEX at the beginning of the project using the H1.3 as HaaS.

INCREASE YOUR MARKET SHARE

Increase your market share by serving industries that are not digitized.

RELIABLE, ROBUST AND SCALABLE

This means that our solution allows data captured by H1.2 sensors to be delivered to the most diverse platforms. The installation process is quick, and in a few minutes you will have vibration and temperature data for your solution, be it Data Analytics, Machine Learning, Digital Twin and many others!

Get the digitalization kit to start developing complete solutions for Industry 4.0

Discover the Hedro family of products

Sensor H1.3

The H1.2 is a vibration and temperature sensor that allows you to monitor machines and industrial processes in real time. They are wireless sensors, with magnetic attachment for simple and quick installation. Installation in 3 steps: fixed, connected and configured. Ready! Your data is already being captured and sent..

BENEFITS:

- Wireless

- Battery that lasts 5 years

- Flexible

- Robust

- Easy to user

- Remote configuration

ACCURACY AND ROBUSTNESS

The HD25 Sensor was specifically developed to measure the distance between two points with micrometric precision in aggressive environments, such as mining, steelmaking and other heavy industries.

Learn about the application of the sensor in lamination.

Application: used to measure the distance between rolling rolls in real time.

HD25 Sensor

HG3 Gateway

The HG3 Gateway is responsible for capturing data from the sensors (H1.2 and HD25) and sending them via the internet network (wi-fi or ethernet).

Our collectors can connect more than 250 sensing points, with a range of 70m. Your data is transmitted securely and quickly.

The sensors can move between collectors without losing connection, making it possible to monitor mobile machines and forklifts, for example.

Do you have any questions?

Send us a message!

+55 (31) 97513-3910

2024 Hedro © Todos os direitos reservados.